What is the concrete moisture test used for?

The Moisture Vapor Emission test, governed by ASTM F 1869, is a concrete test used to measure the weight of water emitting from concrete. The value is used to determine if a concrete subfloor is in the right state to install a resilient flooring system (epoxy coating, laminate flooring, carpet, …). The concrete test employs a puck of dry calcium chloride in a sealed environment. The calcium chloride absorbs water, and the weight gain is used to calculate the weight of water emitted in a 24-hr period over 1000 sq feet.

When and why would you need a concrete moisture test?

Flooring contractors and concrete testing firms use the MVER test to determine if a concrete subfloor has a moisture emission rate (MVER) that is adequate for the flooring type and adhesive. If the MVER of the concrete subfloor is too high, the contractor must delay the installation of the resilient floor until the concrete MVER reduces below specified values (generally below 5.0). When the MVER is below the specified value, the moisture-sensitive adhesives can be applied with little concern of failure of the resilient flooring system.

The MVER is used to determine the moisture vapor emission rate of the concrete. If the MVER is not below the manufacturer’s specified value (generally above 5.0), the adhesive is susceptible to breakdown (hydrolysis), and the following concrete occurs with the resilient flooring system:

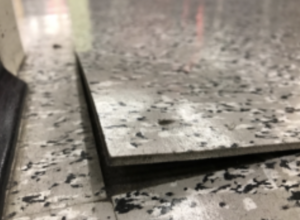

Edge Delamination of VCT

Center Delamination of VCT

Joint/Crack Delamination of VCT

In the case of the resilient flooring system failure, a concrete testing firm can use the MVER test to evaluate the in-place concrete subfloor for MVER. The value that is calculated from the recorded subfloor measurements is compared to the manufacturer’s specified MVER limits. This comparison is often used in dispute resolution when stores that are servicing customer experience loss in revenue due to resilient floor system failures and repairs.

What equipment is used during concrete moisture testing?

-

- Moisture Vapor Emission Packet

- Calcium Chloride Puck

- Plastic Dome with Adhesive

- Litmus Paper

- Distilled Water

- Gram Scale with 0.01 g accuracy

- Equipment to remove resilient floor (VCT, carpet, …) and adhesive without the use of water

- Calculator

What’s the concrete moisture test process?

-

- Step 1: Secure testing area that will not be disturbed for at least 72-hrs.

- Step 2: Remove the resilient flooring system down to bare concrete without the use of water.

-

- Step 3: Acclimate relative humidity and temperature of the environment (store) to be tested to normal use or 75°F (+/-10°F) and 50% (+/-10%) relative humidity and maintain these conditions 48 hours prior to and during MVER testing.

- Step 4: Pre weigh the Calcium Chloride Puck from the MVER testing package, time and date stamp the weight and record the temperature and RH of the testing environment.

- Step 5: Seal the open Calcium Chloride Puck under the Plastic Dome from the MVER package. Reinforce the sides of the Plastic Dome with duct tape or waterproof tape.

- Step 6: Protect the test setup from being disturbed for 72-hrs.

- Step 7: After 72-hrs, remove the plastic dome and weigh the Calcium Chloride Puck, time and date stamp the weight and record the temperature and RH of the testing environment.

- Step 8: Use the change in weight along with the MVER algorithm provided by the MVER package manufacturer to determine MVER in lbs per 1000 sq feet per 24-hrs.

- Step 9: Compare the allowable MVER to the measured MVER for installation.

Can I just say what a relief to uncover an individual who really understands what theyre talking about on the web. You certainly know how to bring a problem to light and make it important. More people ought to read this and understand this side of the story. I was surprised that you arent more popular given that you most certainly have the gift.